Zovala zamatabwandi zida zimene amagwiritsidwa ntchito podula, kusema, kapena kupala matabwa.Kusankha zinthu moyenera ndi luso logwiritsa ntchito kumatha kupititsa patsogolo mphamvu komanso moyo wautali wa tchiselo zamatabwa.Nawa malingaliro ena pakusankha zinthu zamatabwa ndi luso logwiritsa ntchito:

Zosankha:

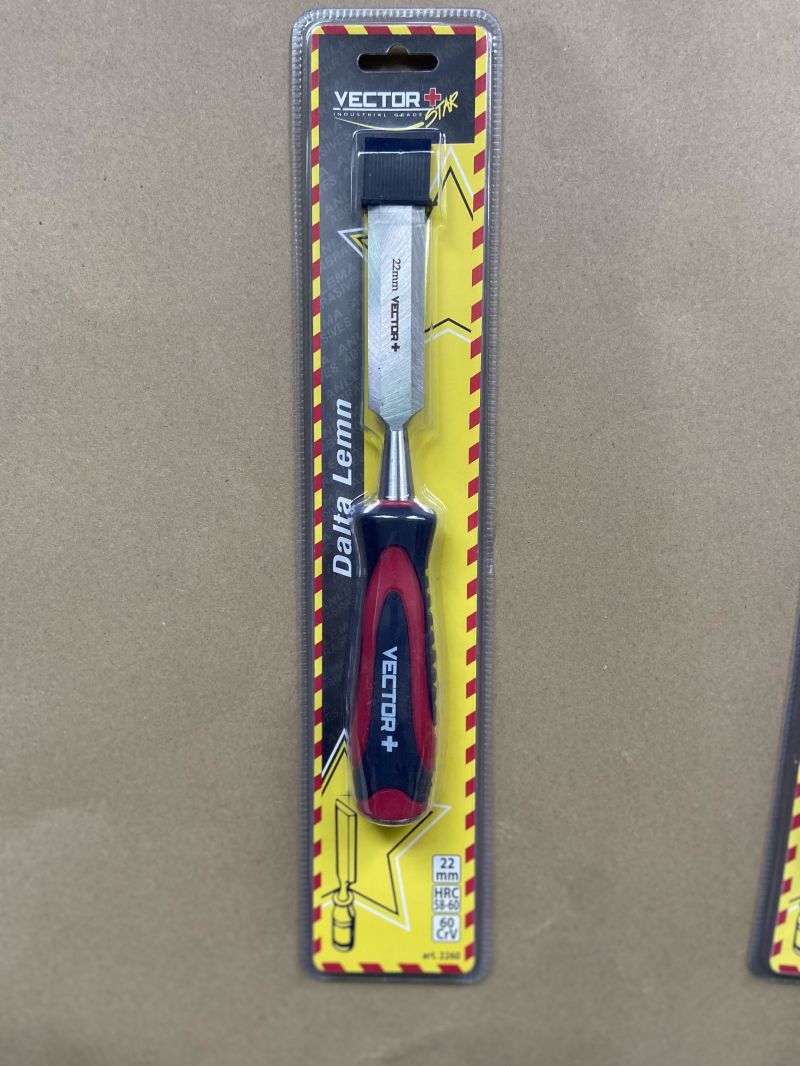

1. Chitsulo chapamwamba cha carbon: Chitsulo chokhala ndi mpweya wambiri ndi chinthu chodziwika bwino pazitsulo zamatabwa, zomwe zimapereka mphamvu zabwino komanso zolimba.Ndizoyenera mitundu yambiri ya matabwa, makamaka matabwa olimba ndi matabwa okwera kwambiri.

2. Chitsulo chothamanga kwambiri: Chitsulo chothamanga kwambiri ndi chinthu chokhala ndi kuuma kwambiri komanso kukhazikika kwa kutentha.Nthawi zambiri amagwiritsidwa ntchito pogwira matabwa olimba kapena zinthu zomwe zimafuna kudula kwambiri.

3.Tungsten alloy: Tungsten alloy ndi chinthu champhamvu kwambiri komanso chosavala chomwe chimagwiritsidwa ntchito popanga tchipisi tamatabwa apamwamba kwambiri.Ndi yoyenera kugwira ntchito ndi matabwa olimba, plywood, ndi zipangizo zophatikizika.

Kuumacha chisel cha matabwa chimadalira zinthu zomwe zimapangidwa.Mitengo yamatabwa nthawi zambiri imapangidwa kuchokera ku chitsulo cha carbon high, high-liwiro, kapena tungsten alloy, omwe ali ndi milingo yolimba yosiyana.Nawa mitundu pafupifupi kuuma kwa zida izi:

1. Chitsulo cha carbon High-carbon: Chitsulo cha carbon high-carbon chomwe chimagwiritsidwa ntchito pazitsulo zamatabwa nthawi zambiri chimakhala cholimba kuyambira 55 mpaka 62 HRC (Rockwell Hardness Scale).Mlingo wa kuuma uku kumapangitsa kuti chisel ikhalebe chakuthwa ndikukana kuvala pakagwiritsidwa ntchito.

2. Chitsulo chothamanga kwambiri: Chitsulo chothamanga kwambiri chomwe chimagwiritsidwa ntchito pazitsulo zamatabwa chimadziwika ndi kuuma kwake kwapadera.Nthawi zambiri imakhala ndi kuuma kosiyanasiyana kwa 62 mpaka 67 HRC, kumapereka kusungika m'mphepete komanso kukana kutentha ndi kuvala.

3. Tungsten alloy: Tungsten alloy chisel ndizovuta kwambiri komanso zolimba.Nthawi zambiri amakhala ndi kuuma kosiyanasiyana kwa 65 mpaka 70 HRC kapena kupitilira apo.Kuuma kwakukulu kwa tungsten alloy kumatsimikizira ntchito yabwino yodula komanso moyo wautali wa zida.

Ndikofunika kuzindikira kuti kuuma kwenikweni kwa chisel chamatabwa kumasiyana malinga ndi mtundu wake, kupanga, ndi chithandizo cha kutentha chomwe chimagwiritsidwa ntchito pa chida.Nthawi zonse tchulani zomwe wopanga amapanga kapena funsani zambiri zamalonda kuti mudziwe kuuma kwa chisel chamatabwa.

Maluso ogwiritsa ntchito:

1. Pitirizani kukhala akuthwa: Kuthwa n'kofunika kwambiri podula tchizila zamatabwa.Yang'anani nthawi zonse tsamba la chisel ndikugwiritsa ntchito mwala kapena chopukusira kuti mukhale wakuthwa.

2. Kuletsa mphamvu yodulira: Mukamagwiritsa ntchito zitsulo zamatabwa, gwiritsani ntchito mphamvu yodulira pang'ono ndikupewa kupanikizika kwambiri.Kugwiritsa ntchito mphamvu mopitirira muyeso kungapangitse tchizilo kumamatira kapena kuwononga tsamba.Gwiritsani ntchito kukankhira pang'onopang'ono ndikupotoza kuti mutsogolere tsamba la chisel pamitengo.

3. Kuyika molongosoka: Musanayambe tchiling'i, lembani malo omwe mukufuna kudula pogwiritsa ntchito rula, pensulo, kapena chida cholembera.Onetsetsani kuti chisel blade yayamba kudula kuchokera pamalo oyenera kuti mupeze zotsatira zolondola.

4. Sankhani mawonekedwe oyenera a tchiseli: Zipatso zamatabwa zimabwera mosiyanasiyana, monga tchiselo lathyathyathya, zozungulira, ndi masikweya.Sankhani mawonekedwe a chisel omwe akugwirizana ndi zofunikira zantchito kuti mupeze zotsatira zabwino.

5. Gwiritsani ntchito mallet: Pazochita zomwe zimafuna mphamvu zambiri, mutha kugwiritsa ntchito nsonga yamatabwa pothandizira kupukuta.Gwirani pang'onopang'ono chogwirira cha chisel kuti mulowetse chitsambacho mumtengo, koma samalani kuti musamalire mphamvuyo ndikupewa kugunda kwambiri komwe kungayambitse kuwonongeka.

6.Njira zodzitetezera: Nthawi zonse muziika patsogolo chitetezo mukamagwiritsa ntchito zitsulo zamatabwa.Onetsetsani kuti matabwawo akhazikika bwino kuti asaterere kapena kuvulala mwangozi.Kuwonjezera apo, valani zida zodzitetezera zoyenera, monga zodzitetezera m'maso ndi magolovesi, kuti mudziteteze pogwira ntchito.

Nthawi yotumiza: Jun-09-2023